Fluid mechanics

For your challenges with air currents, we will look for the right solution

Kostenfreie Service-Line: 0800 – 898 898 0

For your challenges with air currents, we will look for the right solution

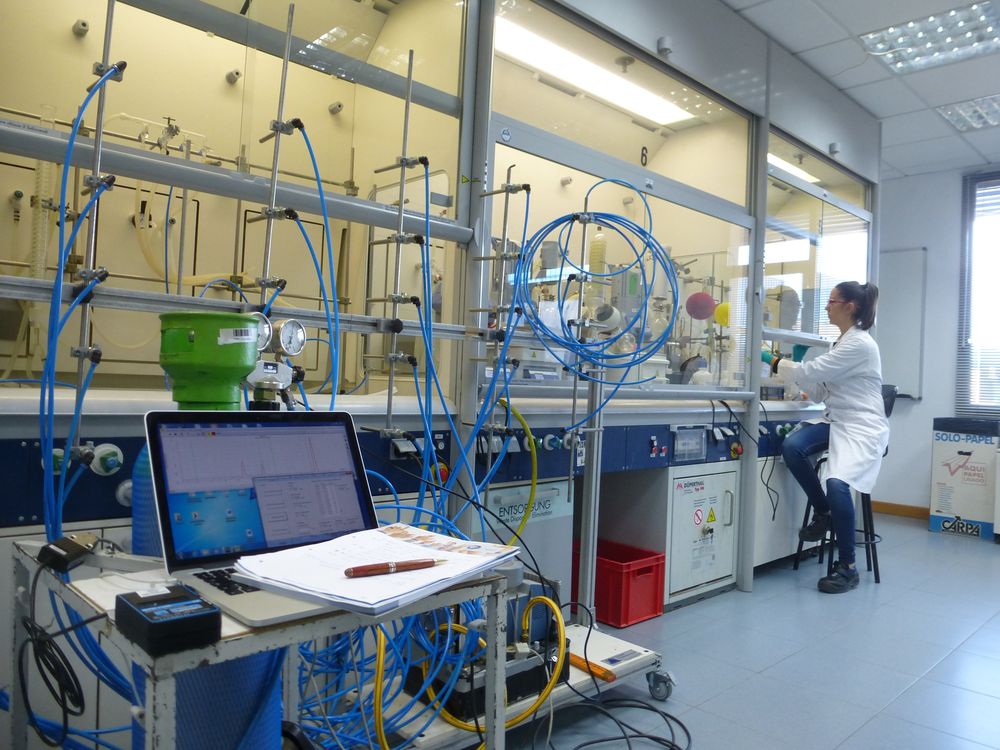

Support for flow measurement and visualization, fume cupboards testing, and many more.

Our fog generators are the ideal aid for making air flows visible in order to understand flow problems.

The Tintschl BioEnergie und Strömungstechnik AG team is working for our customers on-site all over the world.

Air flow conditions to be examined are easier to understand when being visualized. Therefore, already in the beginning of intensive examinations on air flow conditions the FlowMarker® serves as a first indicator, in particular for recognizing areas of special interest within the whole moving air volume.

Further information on our various fog devices can be found here:

Air is not visible. It is therefore not possible to track air flows with the bare eye. But how can the flows of the transparent gas mixture be made observable, for example, to gain important insights in research? The solution is fog.

How fog helps to gain insights and other exciting topics can be found here:

We know the value of rules and standards for the industries in which we operate. That is why membership and direct exchange with the German Institute for Standardization e. V. is so important to us.

The Tintschl BioEnergie und Strömungstechnik AG team is working for our customers on-site all over the world.

91058 Erlangen, Deutschland

Kostenfreie Service-Line:

0800 - 898 898 0

E-Mail:

service@tintschl.de